From start to finish, here’s what we do for your oilfield boiler’s annual maintenance

1

We bring your boiler into the shop and we take off the covers. The handhole plates, manhole plates, inspection plates, plugs, and the front and back doors of the boiler—all are removed.

3

With the firetubes cleaned and free of scale and contaminants, we have a clear view. We inspect the boiler and make any repairs. One example of a repair would be a cracked firetube.

4

ABSA is called in to inspect and certify the boiler.

ABSA (Alberta Boilers Safety Association) is the pressure equipment safety authority for Alberta.

5

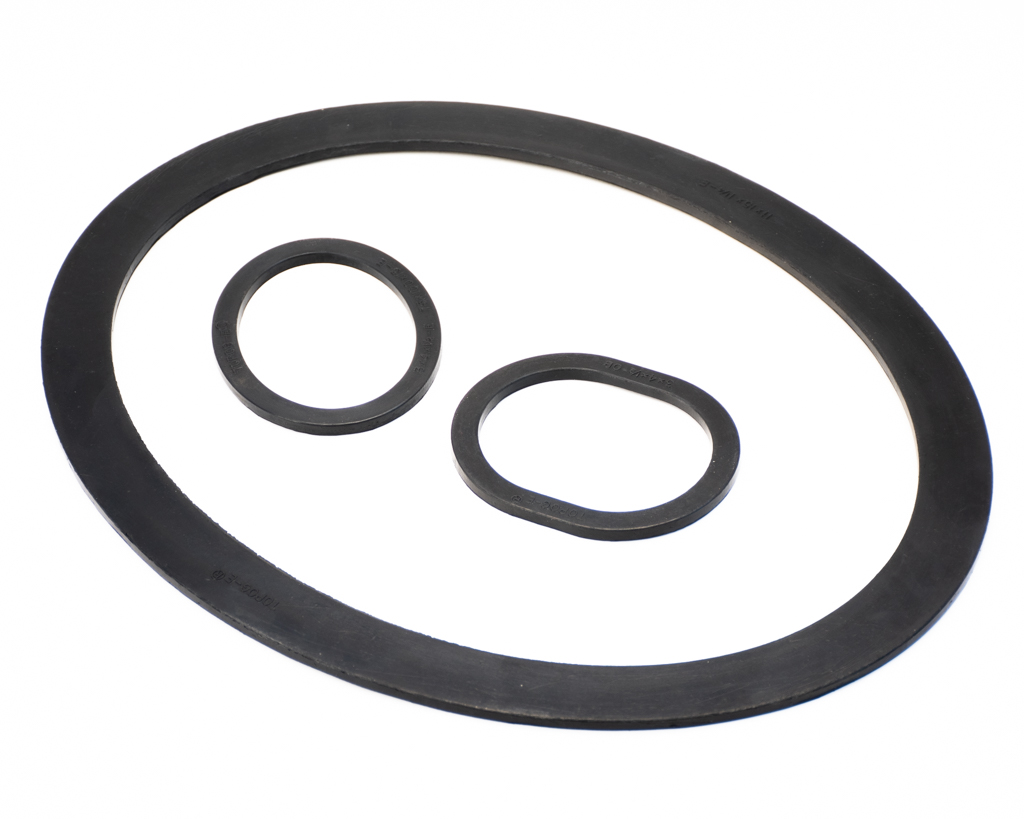

Now that it is certified, the boiler is fitted with NEW gaskets.

6

We seal the pressure vessel and conduct the hydrostatic pressure test. During the test, we inspect the boiler and check for any problems. Any repairs are carried out.

7

If repairs have been made, ABSA comes back to inspect the boiler again.

8

Next we service the burner and put in ALL NEW safety valves. Always.

9

We fire-test the boiler up to steam pressure on both diesel AND natural gas.

During the test, we do a combustion analysis. It helps us ensure that the burner is working at high efficiency.

10

Before we let the boiler go, we wash it again. Now it’s ready for you to pick up.

To book your boiler for maintenance, call 780-955-2723 or send an email to info@arcticboilers.com